Latest News

Setting the Standard: How Sciamed Delivers Grade A Barcode Labels

July 2025

In healthcare, every label matters. A barcode that scans first time, every time, is more than a convenience - it’s a safeguard.

At Sciamed, we take that responsibility seriously. That’s why we only supply ANSI Grade A and B barcode labels, ensuring reliable performance across environments, from pathology labs to pharmaceutical storage.

In our latest blog post, our quality control manager NAME, explains how we maintain our high standards and what this means for our customers.

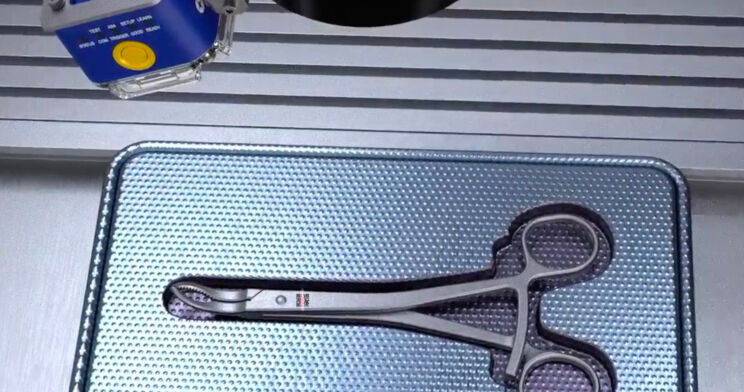

1. Invest in the right materials

High-quality barcodes begin with high-quality materials. We use only premium label stock and adhesives, carefully chosen to withstand demanding environments, from freezing temperatures to chemical exposure.

Choosing the right materials helps prevent smudging, peeling, and degradation, preserving the barcode's integrity from print to scan.

2. Print with precision

We use high-resolution thermal transfer printers, designed to produce crisp, defined lines. These are paired with the optimal ribbon type for each substrate to ensure durability and clarity.

The result? Clean, bold prints that remain scannable throughout the product’s lifecycle.

3. Go beyond standard verification

While many suppliers check barcodes with a basic scan, we go further. Using on-site barcode verifiers, we test:

- The first and last labels of every batch

- Spot checks every 1,000 labels (as a minimum)

- Additional samples depending on the run

These checks are measured against ANSI/ISO 15415 and 15416 standards, assessing factors like contrast, modulation, and decodability. Only barcodes that meet Grade A or B are released.

4. Maintain machines meticulously

Our equipment is maintained to the highest standards with daily cleanings, between-batch checks, and scheduled servicing. Verifiers themselves are also calibrated monthly on site and undergo annual manufacturer health checks to ensure ongoing accuracy.

Because a label is only as good as the machine — and the team — that makes it.

5. Design matters too

Even with perfect materials and printing, a poorly designed barcode can fail. That’s why we follow barcode design best practices, including:

- Correct quiet zones (blank space around the barcode)

- Optimal size and orientation

- Use of scanner-friendly symbologies

This ensures every label is easy to scan — the first time, every time.

6. Quality is continuous

Barcode quality isn’t a one-time job. It’s built into our culture. Through rigorous housekeeping, operator training, and real-time monitoring, we make sure that every label we ship meets our Grade A/B promise.

Why quality matters

Grade C labels might still scan, but they operate on borrowed time. By only delivering Grade A and B standard labels, we help healthcare providers:

- Reduce scanning errors

- Avoid relabelling delays

- Improve workflow efficiency

- Support better patient safety

Because in healthcare, every scan counts.

Planning your pre-printed labels for 2026? Speak with one of our label experts to find out we can help. Contact our team at 1975 564111 or email sales@sciamed.co.uk

For more information, call

01975 564111

or email sales@sciamed.co.uk

July 2025

Why Barcode Label Quality Matters in Healthcare

In healthcare, even the smallest detail can have a significant impact. That’s why at Sciamed, we leave…

April 2025

How to Pick the Perfect Printer (Without the Headache!)

We all know that feeling - you need a new printer, but the options are overwhelming. Do you go for thermal…

September 2024

Shelf-life Control System

Introducing the Safeguarding Shelf-life Control System, a cutting-edge solution dedicated to ensuring the…