Latest News

Saving time, money and mistakes with UDI

March 2020

Patient safety is the top priority for every healthcare provider. To help healthcare providers track and trace all medical devices, manufacturers are now required to apply Unique Device Identification (UDI) to all medical devices from the point of production, during shipment, through the product’s use and finally, to its disposal. Although this is predominantly a safety feature, it has the ability to do so much more.

The data from the UDI allows the manufacturer to store information such as the manufacturer, model, version, serial number and use by date. All of this information can be scanned in an instant and uploaded to the healthcare providers Enterprise Resource Program (ERP). Not only does this save time but a barcode scanner has an error rate of 1 in 10,000,000 characters scanned compared to that of manual data entry which is 1 in 300.

Time spent with the patient is crucial so paired with the appropriate software, the healthcare provider can streamline processes to ensure time isn’t wasted inputting data. The data derived from the UDI can be used to optimise inventory management. This can enable the healthcare provider to implement the first in, first out rule, reduce waste, ensure accurate stock levels and maintain traceability to ease the task of preparing for audits.

The use of the UDI can help to ensure incorrect or expired devices are not used. In the case of recalls, the healthcare provider can quickly establish the location of the medical device and remove it without negatively impacting at the point of care. Faulty medical supplies/devices can be highlighted, located and pulled from the supply chain.

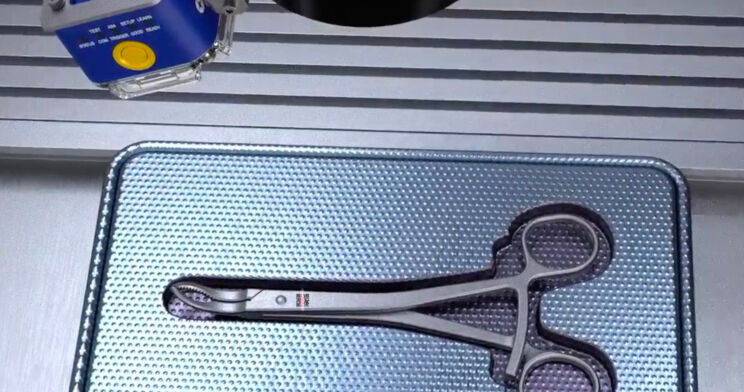

When laser marking is added within the hospitals sterile services department an UDI can be applied to surgical devices allowing it to be traced and tracked throughout the entire cleaning, packing and disinfection process in the hospital decontamination unit. The laser marking process does not affect the passive protective layer of the instrument and can be used on stainless steel, adonised aluminium, titanium and plastic.

Linked below is a case study of the successful implementation of UDI using Datalogic Laser Marking System within NHS Tayside Central Decontamination Unit - Datalogic Case Study.

Not all scanners are created equally, contact Sciamed now to discuss your current scanner and software package and see how you can incorporate the advantages of UDI to your business.

For more information, call

01975 564111

or email sales@sciamed.co.uk

July 2025

Setting the Standard: How Sciamed Delivers Grade A Barcode Labels

In healthcare, every label matters. A barcode that scans first time, every time, is more than a convenience…

July 2025

Why Barcode Label Quality Matters in Healthcare

In healthcare, even the smallest detail can have a significant impact. That’s why at Sciamed, we leave…

April 2025

How to Pick the Perfect Printer (Without the Headache!)

We all know that feeling - you need a new printer, but the options are overwhelming. Do you go for thermal…